Expertise

Three decades of experience in filling technology

Safety and Quality

Where protection is not a luxury, but a standard

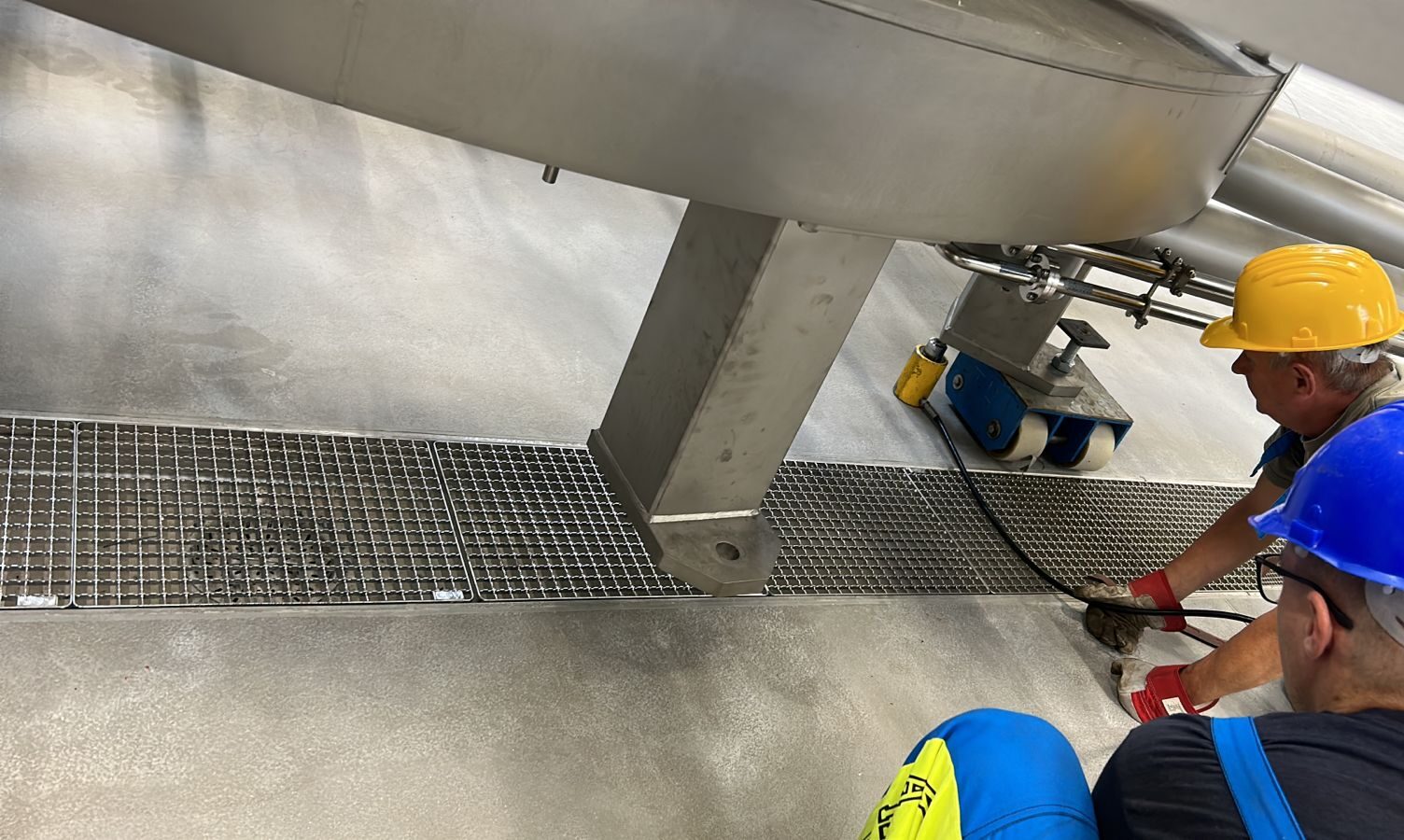

Safety and Quality

Our ISO 9001 and ISO 45001 certifications, along with our KRONES-standard installation process - complemented with floor protection solutions - guarantee smooth, safe commissioning.

Industry Experience

30 years, more than 1000 projects

Industry Experience

Our deep expertise in food and beverage industry environments allows us to install or modernize filling and packaging lines according to hygiene and efficiency requirements, following industry best practices.

Expert Team

Multidisciplinary expertise on all fronts

Expert Team

Our team consists of more than 80 engineers, technicians, electricians, and welders who stay up-to-date through regular internal training. With our multilingual support, communication and handover in international projects is smooth.

Problem-Solving Attitude

You just give the task, we take the burdens

Problem-Solving Attitude

Regardless of whether administrative (permits, documentation) or technical issues arise, we solve them quickly. This allows our clients to truly focus on their business.

Speed and Precision

We deliver on time, without compromises

Speed and Precision

With our installation team of up to 50 people, we start up your production line in the shortest time possible, with detailed milestone documentation. This minimizes downtime, allowing you to start production.

Professional Installation and Equipment

The most modern technology in our hands

Professional Installation and Equipment

Laser measuring devices, special welding equipment, and KRONES-compatible tools ensure optimal fit. With our beautiful cable management, we deliver not only functional but also aesthetically pleasing installations.